A chemical plant in Guangdong, specializing in the production and distribution of non-hazardous chemicals, raw pharmaceuticals, formulations, and industrial materials, required precise monitoring of liquid levels in solution tanks to accurately measure chemical flow rates and sales volumes during transfers, sampling, and distribution. Traditional manual bucket-counting methods were time-consuming, labor-intensive, error-prone, and incompatible with the plant’s demands for rapid, high-quality development.

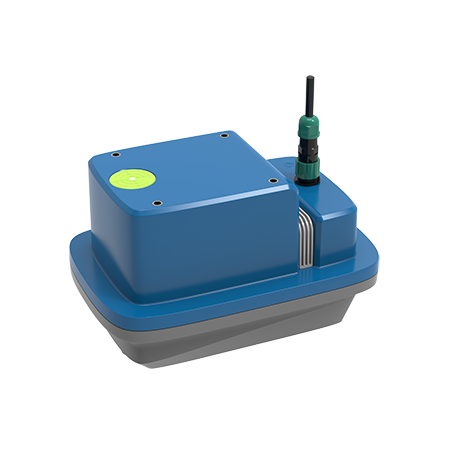

Integrated Radar Level Meter by ShenZhen Huaju Scientific Instruments

To address these challenges, the plant deployed Huaju Scientific’s non-contact integrated radar level gauges, which deliver:

High precision and compact design: Easy installation with millimeter-level accuracy.

Remote management: Configurable and maintainable via cloud-based platforms.

Real-time data integration: Level measurements are instantly uploaded to the plant’s management cloud for live monitoring and archiving, reducing labor costs by 80% and enhancing operational efficiency.

Advanced Technology and Features

This all-in-one radar level gauge integrates multiple functionalities, including:

Built-in rechargeable battery

RTU data transmission module

Bluetooth parameter adjustment

Temperature measurement capabilities

Measurement Principle

The device calculates flow rates based on level-to-flow relationships, converting precise liquid level data into real-time and cumulative flow outputs. It employs Precision Coherent Radar (PCR) technology, surpassing traditional pulse radar systems with higher accuracy and lower power consumption. Utilizing 60GHz/80GHz millimeter-wave radar signals, it ensures:

Non-contact operation

Immunity to corrosion, temperature gradients, air pressure, vapor, bubbles, and sediment

Compact, energy-efficient design

Longevity and Adaptability

The built-in battery offers up to 5 years of service life (actual lifespan depends on factors such as sampling frequency, data upload frequency, network signal quality, and ambient temperature).

Operational Advantages

Non-intrusive installation: Preserves fluid dynamics while enabling millimeter-level precision.

Cloud-enabled efficiency: Built-in RTU enables rapid wake-up and direct data uploads for real-time monitoring of liquid levels and flow trends.

Remote maintenance: Parameters, configurations, and firmware upgrades can be adjusted remotely, eliminating on-site visits and reducing overall operational costs by 30%.

By replacing outdated manual methods with this cutting-edge solution, the plant has achieved modernized, data-driven management, ensuring accuracy, safety, and cost-effectiveness in its daily operations.