Solution Overview

Accurate level monitoring and control in chemical storage tanks are critical to industrial production efficiency. Common level measurement methods include:

Physical Methods: Manual measurement, optical level gauges.

Electronic Methods: Ultrasonic, pressure-based, and radar level gauges.

Limitations of Traditional Methods:

Manual Measurement: Simple but error-prone, unsuitable for continuous monitoring.

Optical Level Gauges: Rely on light refraction, sensitive to temperature, color, and turbidity; only work with non-crystallizing, stable liquids.

Pressure-Based Gauges: Affected by liquid temperature, viscosity, crystallization, and sedimentation.

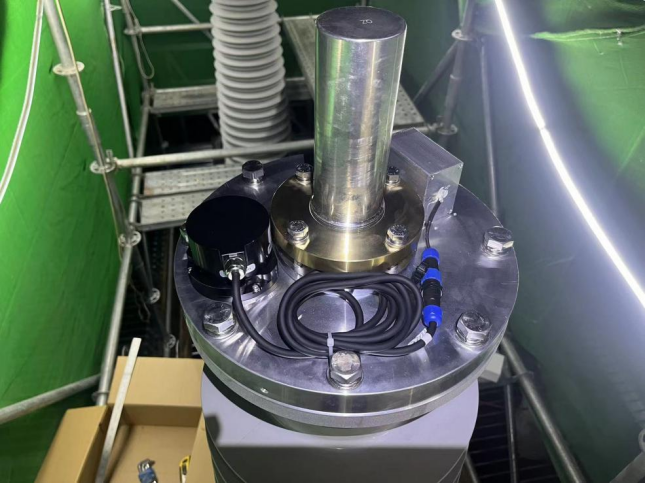

ShenZhen Huaju Keyi Radar Level Gauge

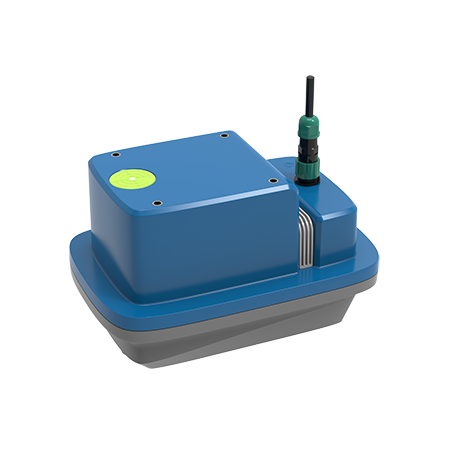

A high-precision, low-power, non-contact integrated solution with the following features:

Advanced Technology:

Pulse Coherent Radar (PCR): Delivers higher accuracy and lower power consumption than traditional pulse radar.

60GHz/80GHz Sub-Millimeter Waves: Ensures compact design, energy efficiency, and immunity to corrosion, temperature gradients, vapor, bubbles, and sediment.

Integrated Design:

Combines power supply (built-in battery), RTU data transmission, Bluetooth configuration, and temperature measurement.

5-Year Battery Life: Actual lifespan depends on sampling frequency, data upload rate, network signal quality, and environmental conditions.

Key Advantages:

Non-Contact Installation: Avoids interference with fluid dynamics; millimeter-level precision.

IP68 Waterproof Rating: Resists submersion and harsh weather.

RTU Integration: Direct cloud data upload for real-time monitoring.

Remote Management: Debugging, parameter adjustment, and firmware upgrades via Bluetooth or cloud platforms, reducing maintenance costs.

体积小巧,安装简单,非接触安装便于传感器和被测液体不接触,不干扰流体流态,毫米级高精度测量液位,计量更准确。内置RTU,快速唤醒,数据直接上传管理云平台,能实时监控液体液位变化。IP68高防水设计,浸入水中也不会损坏,适合各种天气环境。远程调参、配置和升级,不用去现场就可以调试、维护,提高工作效率,方便快捷,降低了维护成本。